The plumbing design for a complex processing system doesn’t have to be extremely difficult when there is cooperation among team members.

by Paul Freeman, PE, CPD

Six million—yes, that’s correct—six million eggs are processed through Vital Farms in Springfield, Missouri each day thanks to a recent expansion project that increased the output from three million eggs per day. The facility receives eggs from nearby farms and distributes them all over the United States.

I was fortunate to be part of the engineering team that provided the MEP design required for the egg processing. The construction manager, Sandpebble Project Management, was instrumental to the success of the project from design through construction. Having been the construction manager on the original project, they were aware of problems as well as what worked best for constructability. Just as noteworthy was the feedback and help from the end users who provided us with a wish list of items to include and avoid. Coordinating this with the complex technical requirements of the processing machinery and facility created an intricate and triumphant plumbing engineering experience.

Plumbing Design Challenges

The existing facility remained operational during the expansion, and the new process is independent of the original facility. The expansion project used the original facility as a template for the design. Process demands such as different water temperatures, pressures, compressed air, and graywater and sanitary black water separation provided a complex plumbing design. The graywater is what the facility calls “clean” water, and it must be drained and carried separately from sanitary black water, with no black water piping or cleanouts in the process area. Another challenging demand was that no piping could be overhead, including conduit, domestic water, process water, natural gas, sanitary, and gray/clean.

Breaking Down the Design

Process Water

I’ll start with process and domestic water. High-temperature hot water was used to supply machinery requiring a range of temperatures and pressures. The type of machinery used included egg washing, egg drying, tray washing, pallet washing, parts washing, and egg shell compacting. Calculating a peak water demand was a difficult procedure, but coordination with the end user made this task manageable. In the end we settled on 3 million British thermal units per hour (Btuh) of boiler energy required for a heat exchanger to provide 52 gallons per minute (gpm) of high-temperature water with 3,000 gallons of storage. Three 1,000-gallon storage tanks were selected, but due to room height restrictions, the floor slab was depressed to fit the tanks.

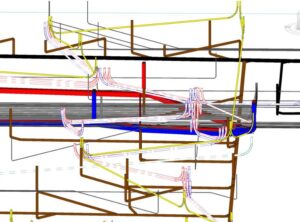

All piping was run below the floor slab and up to each fixture with no fittings below the floor. (See Figure 1 for a partial Revit file showing the underground piping.) This meant that at every fixture, full-size piping would rise above the floor, tee to the fixture, and return back down below the slab to the next fixture.

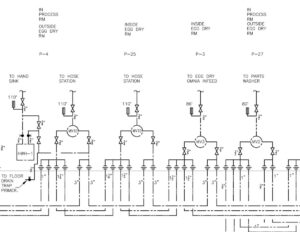

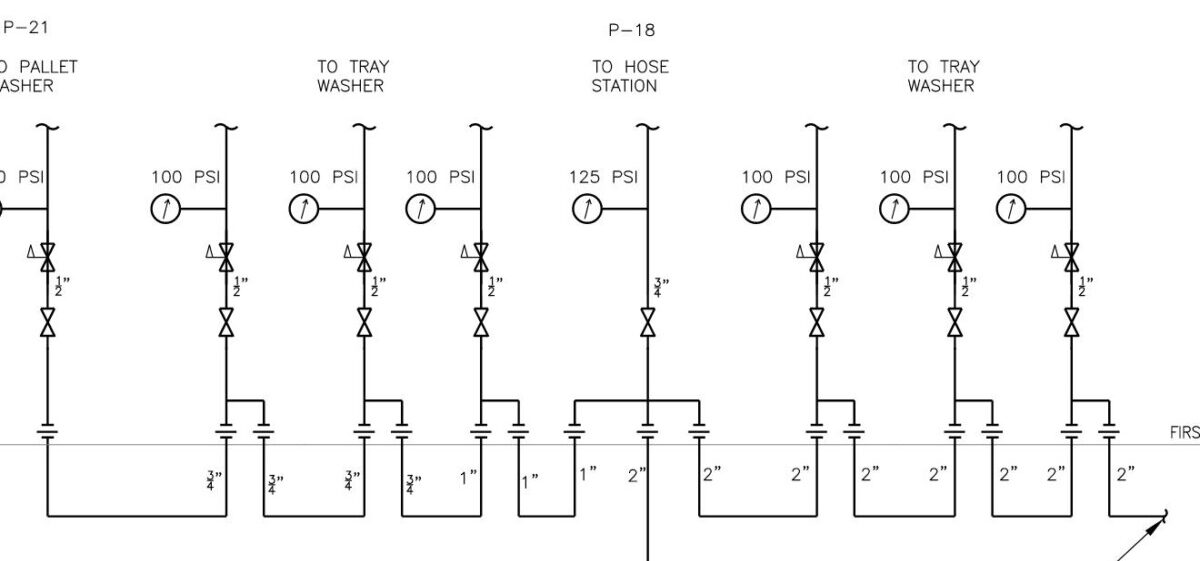

Each fixture was provided with control valves, adjustable mixing valves, and thermometers. PEX tubing was used for the domestic cold water piping below grade, and HDPE was used for the hot water supply and return piping below grade. A hot water recirculating system kept the water to each fixture at a high temperature for “instant” hot water while minimizing Legionella growth. See Figure 2 and 3 for sample riser diagrams.

The piping material was selected for its durability below grade and flexibility for continuous sweep elbows for rising through floor slabs without fittings. In addition to the machinery mentioned above, the process water also fed handwash stations with high-speed blower dryers, high-pressure hot water hose stations (see Figure 4), and emergency fixtures.

Compressed Air and Natural Gas

Compressed air was required for most machinery and the high-pressure hose stations. The existing compressor equipment (to be upgraded as required in the future) was used, and a new 500-gallon storage tank was added to the system piping loop. Flexible HDPE with aluminum in the center layer was used for compressed air piping below the floor slab. Again, this piping needed to “swing” up through the slab to tees and back down below the floor, with valves and gauges at each fixture.

Low-pressure natural gas was used for the boilers and HVAC equipment. To reach the remote HVAC equipment, gas piping had to be run below the floor slab as well. This piping required sleeves/venting in compliance with the IFGC (International Fuel Gas Code). Corrugated stainless steel flexible tubing pre-sleeved with polyethylene was used for the flexibility and venting requirements.

Graywater and Sanitary Black Water

Sanitary/waste systems (black water) from the remote toilets were routed around the processing areas. Graywater (clean water), from approximately 50 large floor drains located throughout the processing area, was routed to one side of the facility and parallel to the sanitary system to the exterior. Clean water vent piping was routed to the nearest interior walls to rise above the floor to the ceilings and run away from the process areas.

The End Result

As you can see from this case study, the plumbing design for a complex processing system doesn’t have to be extremely difficult when there is cooperation between engineers, clients/end users, and contractors. Not every project requires this much teamwork and coordination, so it is nice to have it when available. Installation experience helps on so many levels that having a contractor or someone familiar with the work on your team will be extremely invaluable. Keep this in mind on your future projects: “Good management practices include recognizing engineering resources, the general nature of plumbing engineering projects, and the management of specific projects” (taken from Plumbing Engineering Design Handbook, Volume 1).

So, look for the Vital Farms label and know that those eggs went through a professional, clean, and quality process to get to your kitchen.

Original Article Published Here: https://www.aspe.org/pipeline/case-study-design-team-overcomes-unique-challenges-at-egg-processing-facility/

About the Author

Paul Freeman, PE, CPD, is ASPE’s Region 1 Director. The author was working for Emtec Consulting Engineers, DPC at the time the project was being designed.

Published with permission from Emtec Consulting Engineers, DPC., Sandpebble Project Management and Vital Farms. The opinions expressed in this article are those of the author and not the American Society of Plumbing Engineers.